The Future of Semiconductor Security

The silicon supply chain is both a major enabler and a possible weakness in a society depending more and more on digital infrastructure. From defence systems to cell phones, the semiconductors running everything come from a complicated, worldwide network of designers, fabricators, and distributors. The Future of Semiconductor Security Rising cyber threats, supply interruptions, and geopolitical tensions have turned the security of this silicon chain into a national interest and company survival issue. It is now necessary to guarantee the dependability and robustness of this supply chain, not optional.

Three key phases, design, manufacture, and distribution, at the core of the silicon supply chain define Usually dominated by a small number of businesses such as ARM, AMD, and NVIDIA, who produce intellectual property (IP) driving innovation across several sectors, chip design is A few number of worldwide foundries, especially Taiwan Semiconductor Manufacturing Company (TSMC), Samsung, and Intel, particularly significantly control fabrication, the process of creating the actual silicon wafers. At last, chips must be inspected, packaged, and delivered to customers, a system spanning continents and time zones. Every phase represents a possible point of failure or compromise; the interactions among them greatly increase the stakes.

Recent interruptions have made clear how brittle this supply chain is. The COVID-19 epidemic exposed how easily global production may be disrupted by labour shortages, transport difficulties, and plant closures. Chip shortages drove automotive manufacturers to shut down production lines for months, highlighting how one component can ruin whole industries. More lately, geopolitical concerns, especially U.S.-China tech rivalry, have further disrupted the global semiconductor technology flow. Sanctions, export restrictions, and concerns about espionage or sabotage have intensified the drive toward indigenous industrial capability and safe supply routes.

Apart from causing physical disturbance, the silicon supply chain is becoming susceptible to hardware-level and cyber-attacks. The potential of adding harmful code or hardware backdoors has increased as chips get more sophisticated and depend on open-source components and outside-owned IP. Once incorporated in a product, a hacked chip can be practically undetectable, hence hardware-based assaults are very sneaky. These dangers are real, not speculative. Documented events and plausible claims of compromised components finding their way into consumer products, government systems, and vital infrastructure have surfaced. From design to deployment, maintaining the integrity of every chip call for end-to- end visibility and verification systems.

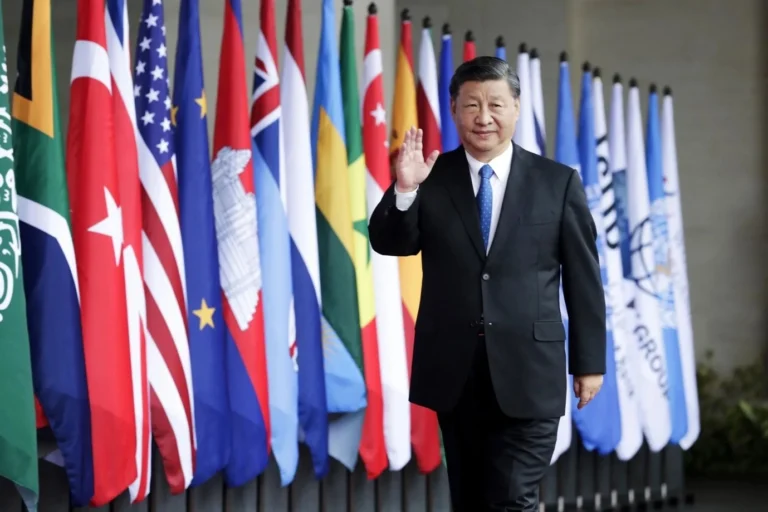

Leaders in government and business are reacting. For instance, the CHIPS and Science Act, a multibillion-dollar expenditure meant to support domestic semiconductor manufacture and research, has been passed by the United States. To lessen reliance on outside vendors, the measure offers subsidies, promotes public-private alliances, and supports workforce growth. In a similar vein, the European Union has proposed its own Chips Act to build a safe digital ecosystem and boost member state production capability. Understanding their strategic relevance, Japan, South Korea, and India are also heavily funding semiconductor capabilities.

Still, money cannot be enough. Getting the silicon chain calls both a thorough and team effort. This includes putting hardware assurance standards, such as those supported by the International Organization for Standardization (ISO) and groups like the Trusted Computing Group into effect. These criteria advance tamper-resistant packaging, supply chain traceability, and safe design ideas. From wafer to warehouse, technologies including digital twins, blockchain, and artificial intelligence-driven anomaly detection are being investigation to track chips through every phase of their lifetime.

Staff and talent development are still quite important as well. Particularly in specialist roles like lithography, materials science, and embedded security, the semiconductor sector suffers a deplete of qualified engineers and technicians. Without a large talent pool, operational restrictions run the danger of undercutting initiatives to regionalize or guarantee chip production. Building and maintaining the human capital needed to protect the silicon chain will depend critically on education initiatives, apprenticeships, and international talent exchanges.

Also quite vital is encouraging global cooperation. Although self-sufficiency is a good objective, no one nation can realistically manage the whole silicon supply chain. Global interdependence is ingrained. To find risks, handle disruptions, and organize recovery, strategic alliances, coordinated rules, and information exchange agreements will be very vital. A safe supply chain is one that is transparent, responsible, and strong rather than one isolated.

Private sector businesses, meantime, must change their procurement and manufacturing practices to have a security-first attitude. This covers routinely evaluating risks, closely reviewing vendors, and funding duplicated sourcing projects. Cybersecurity teams must coordinate closely with product development teams to include security into the early phases of chip design and cover hardware vulnerabilities.

The modern world’s nervous system is the silicon supply chain. Its security influences national defence, economic stability, global innovation, and consumer electronics as well as other areas. Securing this chain is a shared obligation that cuts across boundaries, sectors, and ideas as technological competition gets more fierce and fresh risks surface. Though the road ahead calls vision, effort, and relentless attention, the cost of delay is far more. We guard the future itself in protecting the silicon chain.